Global

International

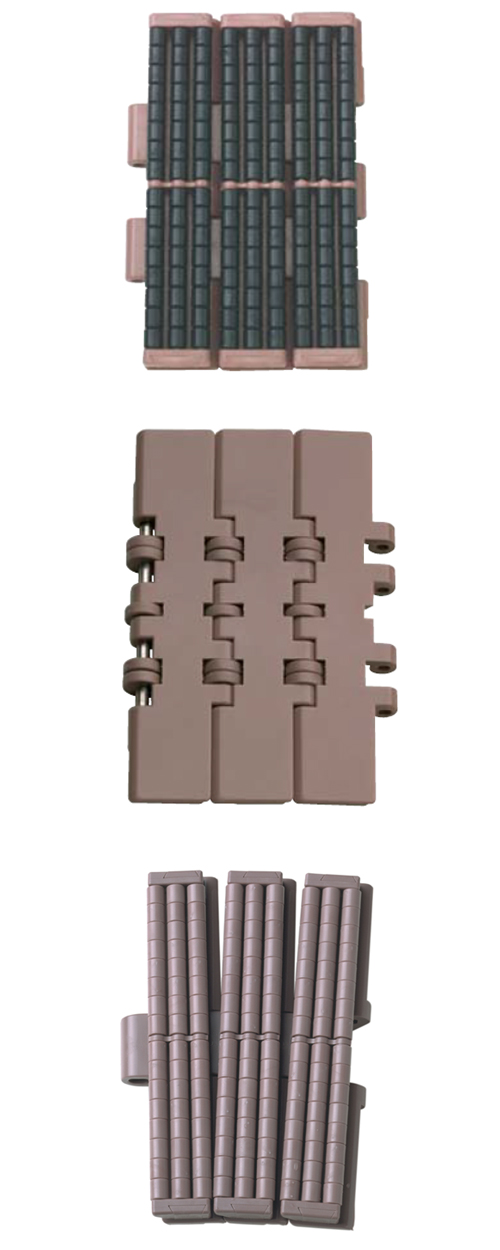

Plastic Chains are a light-weight yet strong and silent alternative to Steel Chains. Plastic Chains are used in many industries; mainly in the Food and Packaging Industry for conveying of various container types.

Our Plastic Chains are available for both straight running and side flexing applications. Side Flexing Chains are available in Tab, Bevel and Magnetic formats to suit different curve holddown systems.

Slat Top Plastic Chains are a type of conveyor chain used mainly in the Food and Packaging Industry for conveying of various container types. We manufacture a very wide range of types and sizes, these are grouped into diffrent sub-type families as listed on the left.

Please select the sub-type groups for further information. These chains are produced to international dimension standards which are commonly used throughout the industry.

Comprehensive range of standard Slat Top Chains.

Used for bottle, can and packaged products transportation.

Product features:

uni 820 Series. Single Hinge Chains

uni 821 Series. Double Hinge Chains

uni 828 Series. Single Hinge Chains

uni 831 Series. Single Hinge Chains

uni 900 Series. Multi Hinge Chains

uni 8257 Series. Single Hinge Chains

Tab Plastic Chains

Comprehensive range of standard Slat Top Chains. Used for bottle, can and packaged products transportation. Tab hold down system for curves.

Product features:

uni 440 Tab Series. Side Flexing Chains

uni 879 Tab Series. Side Flexing Chains

uni 880 Tab Series. Side Flexing Chains

uni 882 Tab Series. Side Flexing Chains

uni 887 TAB Series. Side Flexing Chains

Bevel Plastic Chains

Comprehensive range of standard Slat Top Chains. Used for bottle, can and packaged products transportation. Bevel hold down system for curves.

Product features:

uni 879 Series. Side Flexing Chains

uni 880 Series. Side Flexing Chains

uni 882 Series. Side Flexing Chains

Super Flex Plastic Chains

Comprehensive range of Standard Slat Top Chains. Used for bottle, can and packaged products transportation. Super Flex hold down system for curves.

Product features:

uni 879 Super Flex Series. Side Flexing Chains

uni 880 Super Flex Series. Side Flexing Chains

Commonly used within beverage and bottling industries to ensure reliable stable container handling. Chains used together with magnetic hold down conveyor track systems to ensure chain flights remain flat and do not tilt or lift on curved conveyor sections.

Product features:

uni 879 M Series. Magnetic Chains

uni 880 M Series. Magnetic Chains

uni 882 M Series. Magnetic Chains

Ideal for the Beverage, Container (bottles, cans) and Packaging Industry.

Snap-On Chains are designed with overlapping flights assembled on special roller chains with extended pins. This is an advantage at high speeds as it reduces noise levels.

Overlapping flights are an advantage where people work at tray conveyors; they ensure there are no vertical gaps between the flights so nothing can get caught.

All Snap-On versions can be delivered either with a stainless Steel Chain (SS304) or a carbon Steel Chain.

Snap-On Straight Running Plastic Chains

Plastic links mounted on precision roller chains. Used for higher speed conveyors and longer conveyors.

Product features:

uni 843 Series. Straight Running Chains

uni 863 Series. Straight Running Chains

uni 963 Series. Straight Running Chains

Snap-On Straight Running Tab Plastic Chains

Plastic links mounted on precision roller chains. Used for higher speed conveyors and longer conveyors. Tab hold down system for conveyor tracks.

Product features:

uni 863 Tab Series. Straight Running Chains

uni 963 Tab Series. Straight Running Chains

Snap-On Side Flexing Tab Plastic Chains

Plastic links mounted on precision roller chains. Used for higher speed conveyors and longer conveyors. Tab hold down system for conveyor curves and tracks.

Product features:

uni 1843 Tab Series. Side Flexing Chains

uni 1873 Tab Series. Side Flexing Chains

uni 3873 Tab Series. Side Flexing Chains

Comprehensive range of universal Case Chains. Mainly used for case / crate handling.

Product features:

Straight Running Case Chains

Comprehensive range of universal Case Chains. Mainly used for case / crate handling.

Product features:

uni NH78 Series. Open Case Chains

Side Flexing Case Chains

Comprehensive range of universal Case Chains. Mainly used for case / crate handling.

Product features:

uni 2600-O Series. Open Side Flexing Case Chains

uni 2600-C Series. Closed Side Flexing Case Chains

uni 2600 Tab Series. Open Side Flexing Case Chains

uni 2600 Tab Series. Closed Side Flexing Case Chains

uni 1400 Series. Open Side Flexing Case Chains

uni 1400 Tab Series. Open Side Flexing Case Chains

uni 2800 Series. Open Side Flexing Case Chains

uni 2800 Tab Series. Open Side Flexing Case Chains

uni 2500 Series. Closed Side Flexing Case Chains

uni 2700 Series. Side Flexing Case Chains

uni 3200 Series. Tab Side Flexing Case Chains

uni 3000 Series. Side Flexing Case Chains

uni 610 ML Series. Crescent Moon Link

Comprehensive range of universal Cardanic Chains. Used for bottle, carton and packaged products transportation.

Product features:

uni 1700 Series. Universal Cardanic Chains

uni 1701 Series. Universal Cardanic Chains

uni 1702 Series. Universal Cardanic Chains

uni 1703 Series. Universal Cardanic Chains

uni 1704 Series. Universal Cardanic Chains

uni 1705 Series. Universal Cardanic Chains

uni 1706 Series. Universal Cardanic Chains

uni 550 Series. Multi-Flex Finger Protection Chains

Range of Side Flexing Gripper Chains. Used for gripper elevators and container inverters. Tab hold down system for conveyor curves and tracks.

Product features:

Range of Side Flexing Gripper Chains. Used for gripper elevators and container inverters. Tab hold down system for conveyor curves and tracks.

Product features:

uni 1873 D Series. Snap-On Tab Side Flexing Grip Chain

uni 1873 G4. Snap-On Tab Side Flexing Grip Chain

uni 1873 G4L. Snap-On Tab Side Flexing Grip Chain

uni 1873 G3. Snap-On Tab Side Flexing Grip Chain

uni 1843 EG Series. Edge Gripper Chain

Range of Side Flexing Gripper Chains. Used for gripper elevators and container inverters. Tab hold down system for conveyor curves and tracks.

Product features:

uni 879 Tab R G4. Side Flexing Slat Top Grip Chain

Used for product accumulation with low back-line pressures. Sometimes used to create gaps between conveyed products.

Product features:

uni 821 LBP Series. Straight Running, Double Hinge Chain with rollers on top surface (5 mm pins).

uni 821 RO Series. Straight Running, Double Hinge Chain with rollers on Chain Hinges.

uni 821 PRR 4 Series. Straight Running, Double Hinge Chain with rollers on top surface (4 mm pins).

uni 8257 LBP BP Series. Backline Pressure Reduction Rollers

uni 882 LBP TAB BP Series. TAB Backline Pressure Reduction Rollers

uni 882 LBP M BP Series. Magnetic Backline Pressure Reduction Rollers

Range of Side Flexing Rib Chains.

Product features:

uni 880 Rib Series. 8% open, suitable for fairly large items, based on 880 Chains series.

uni 880 Rib Flex Series. Shorter Rib distance for smaller items, based on 880 Chains series.

uni 882 Rib Flex Series. Shorter Rib distance for smaller items, based on 882 Chains series.

Range of Slat Top Chains.

Product features:

uni 879 Tab Series.

uni 879 Tab SF Series.

uni 882 Tab Series.

uni 982 SC Series.

The limit for the incline of a chain conveyor without the problem of products sliding back is usually 3-4 degrees. For higher inclines, the solution is a chain with moulded rubber inserts.

uni moulded rubber inserts are available in various hardnesses and can be supplied for all uni Slat Top chains, Snap-On chains and some uni Flex chains.

Straight running hybrid chain.

Product features:

A range of side flexing chain belts with thicker top flight plates. These chain belts are often used together with our modular belts of same flight thickness.

Product features:

AVE 2503 FT TAB Series. Flat Top TAB

AVE 2503 FT M Series. Flat Top Magnetic

AVE 2503 FT Series. Flat Top Bevel

AVE 2505 FT TAB Series. Flat Top TAB

AVE 2505 FT M Series. Flat Top Magnetic

AVE 2505 FG M Series. Flush Grid Top Magnetic

AVE 2505 FT Series. Flat Top Bevel

uni 7253 TAB Series. TAB

uni 7253 Series. Bevel

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.