Global

International

The way ZipLink® is built removes any potential weak spots, being more durable than seamed or fused belts. Even after repair, the belt remains as strong as before.

ZipLink® avoids fasteners that could damage the product, making our customers safer and independent of external services for the on-site splicing. What is more, one ZipLink® roll can cover all positions of the same width, helping with stock optimisation.

The ZipLink® range was created to meet the needs of multiple applications in many segments, such as Corrugated board, Wood, Insulation, Logistics, Tyre, Ceramics, and more. All in all, ZipLink® range provides a reliable, effective, and adaptable solution for belting applications.

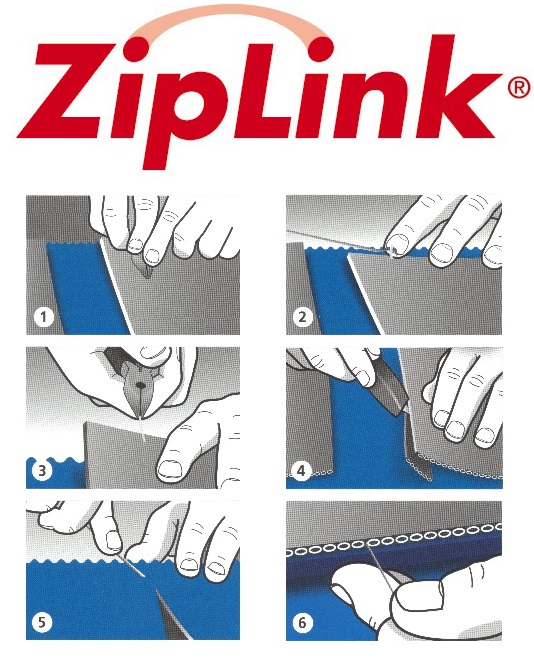

ZipLink® range is a highly practical and cost-effective belting solution for various industries and purposes. Its unique mesh structure allows for convenient splicing without special tools, reducing downtime and increasing productivity. What is more, it can be customised with a variety of top-cover materials.

Read more

During their conveying process, the movement of the ceramic tiles on the belt can quickly deteriorate its coating, leading to continuous repairs and maintenance expenses.

Non-slip, high-abrasion and chemical resistant, ZipGuide belts are designed to keep your ceramic tiles safe at every stage of your production process.

Read more